A desuperheater is a device used in various systems. It helps control temperature. It is often used in heating, ventilation, and air conditioning (HVAC) systems. It is also found in industrial processes.

What is Superheat?

Superheat is when steam is hotter than its boiling point. For example, water boils at 100°C. If steam is above 100°C, it is superheated. Superheated steam has extra energy. This energy can be useful, but sometimes we need to lower it.

Why Use a Desuperheater?

Desuperheaters lower the temperature of superheated steam. This process is important for several reasons:

- Protects equipment from damage.

- Improves efficiency.

- Ensures safety.

Superheated steam can harm equipment. High temperatures can cause wear and tear. This can lead to breakdowns. Desuperheating helps prevent this. Lower temperatures also mean less energy waste. This improves system efficiency. Finally, it ensures safety. Extremely hot steam can be dangerous.

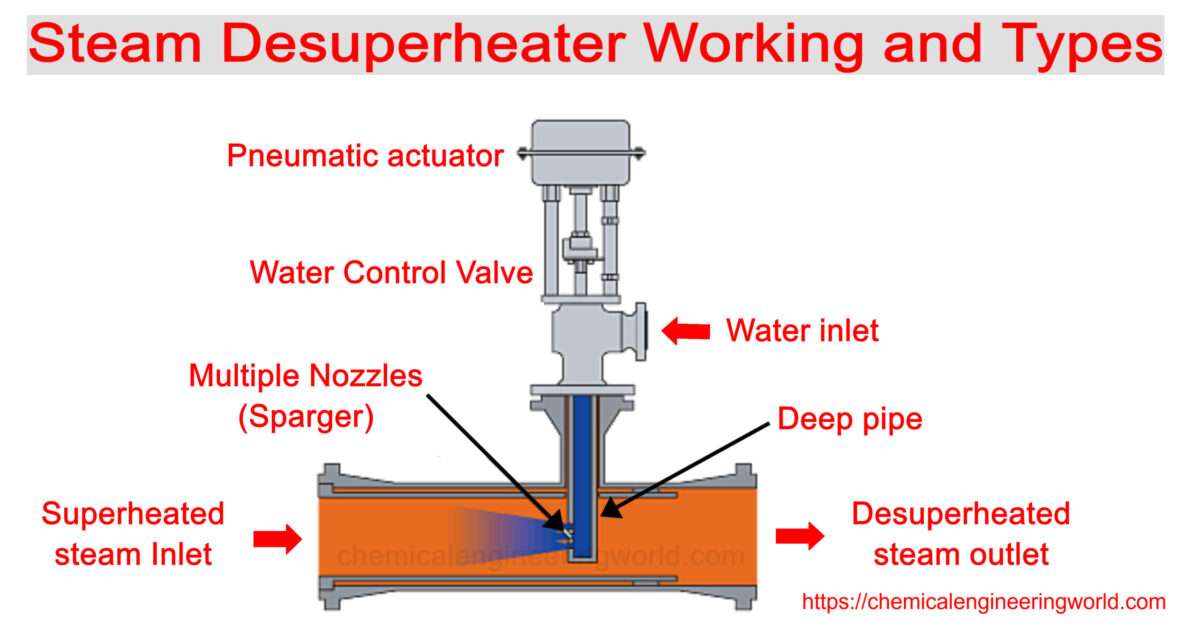

Credit: chemicalengineeringworld.com

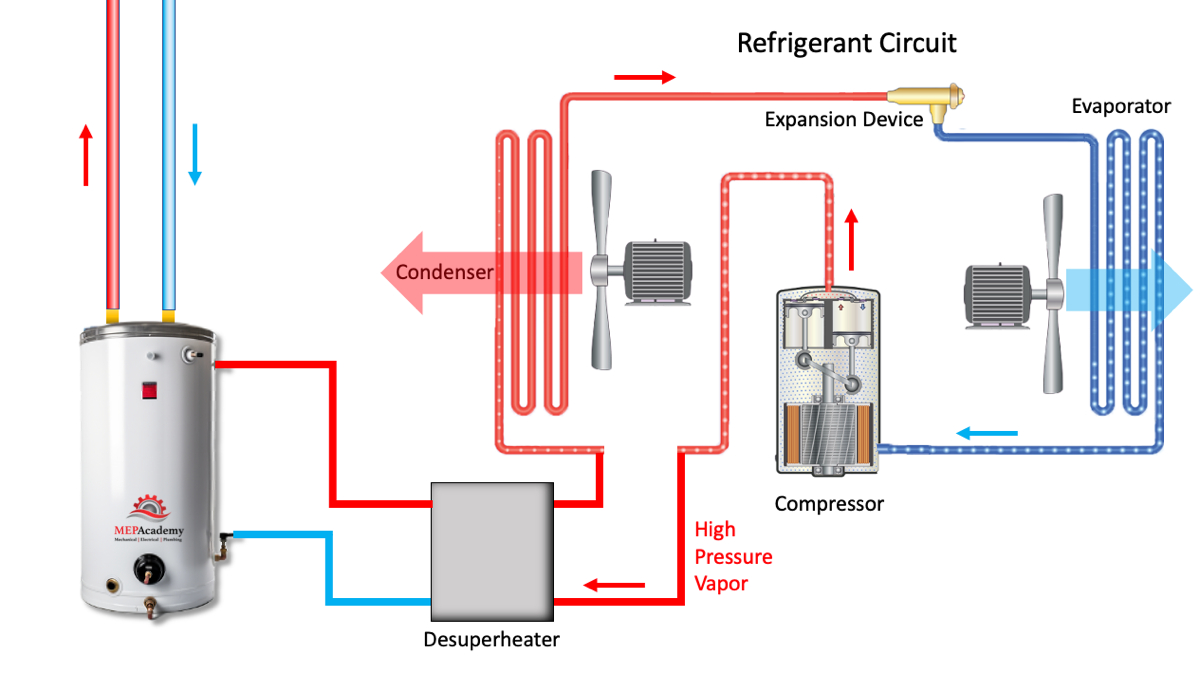

Credit: mepacademy.com

How Does a Desuperheater Work?

A desuperheater works by mixing steam with water. This cools the steam. There are different types of desuperheaters. The most common types are:

- Spray type desuperheater

- Venturi type desuperheater

- Surface type desuperheater

Spray Type Desuperheater

This is the most common type. In a spray type desuperheater, water is sprayed into the steam. The water absorbs the heat from the steam. This lowers the steam’s temperature.

Here is a simple diagram:

| Component | Function |

|---|---|

| Steam Inlet | Where the superheated steam enters. |

| Water Nozzle | Sprays water into the steam. |

| Mixing Chamber | Where steam and water mix. |

| Steam Outlet | Where the cooled steam exits. |

As the steam passes through the mixing chamber, it cools down. The cooled steam exits through the steam outlet.

Venturi Type Desuperheater

In a Venturi type desuperheater, steam flows through a narrow section called a Venturi. The narrow section increases the steam’s velocity. Water is then injected into the high-velocity steam. The water quickly mixes with the steam, cooling it down.

Here is a simple diagram:

| Component | Function |

|---|---|

| Steam Inlet | Where the superheated steam enters. |

| Venturi | Narrow section that increases steam velocity. |

| Water Injection Point | Where water is injected into the steam. |

| Mixing Chamber | Where steam and water mix. |

| Steam Outlet | Where the cooled steam exits. |

The high-velocity steam helps the water mix quickly. This cools the steam effectively.

Surface Type Desuperheater

In a surface type desuperheater, steam flows over a cooled surface. The surface is usually a metal tube. Water flows inside the tube. The steam transfers its heat to the metal tube. The metal tube then transfers the heat to the water inside.

Here is a simple diagram:

| Component | Function |

|---|---|

| Steam Inlet | Where the superheated steam enters. |

| Metal Tube | Surface where steam transfers heat. |

| Water Inlet | Where cooling water enters the tube. |

| Water Outlet | Where heated water exits the tube. |

| Steam Outlet | Where the cooled steam exits. |

This method is less common but very effective. It does not mix water directly with steam. Instead, it uses a cooled surface to lower steam temperature.

Applications of Desuperheaters

Desuperheaters are used in many industries. Some common applications include:

- Power plants

- Refineries

- Pulp and paper mills

- HVAC systems

In power plants, desuperheaters help control steam temperature. This improves turbine efficiency. In refineries, they protect equipment from high temperatures. In pulp and paper mills, they are used in steam processes. In HVAC systems, they help control air temperature.

Benefits of Using Desuperheaters

Using a desuperheater has several benefits:

- Protects equipment

- Improves efficiency

- Ensures safety

- Reduces energy waste

By lowering steam temperature, desuperheaters protect equipment. This reduces wear and tear. It also improves system efficiency. Lower temperatures mean less energy waste. Finally, it ensures safety. Extremely hot steam can be dangerous. Desuperheaters help prevent accidents.

Frequently Asked Questions

What Is A Desuperheater?

A desuperheater reduces steam temperature by injecting water.

How Does A Desuperheater Work?

A desuperheater injects water into steam, cooling it.

Why Is Desuperheating Important?

Desuperheating ensures efficient steam usage and prevents equipment damage.

Where Are Desuperheaters Used?

Desuperheaters are used in power plants and heating systems.

Conclusion

Desuperheaters are important devices in many systems. They lower the temperature of superheated steam. This protects equipment, improves efficiency, and ensures safety. There are different types of desuperheaters. The most common types are spray type, Venturi type, and surface type. Each type works in a different way but has the same goal. Lowering the temperature of superheated steam.

Understanding how a desuperheater works is important. It helps us appreciate the role they play in various industries. They are small but crucial devices. They help keep systems running smoothly and safely.