Busbar trunking systems are important in electrical setups. They help distribute electricity. Let’s learn about their parts. These parts are called components.

What is Busbar Trunking?

Busbar trunking is a system that carries electricity. It is used in big buildings and factories. This system is safe and reliable.

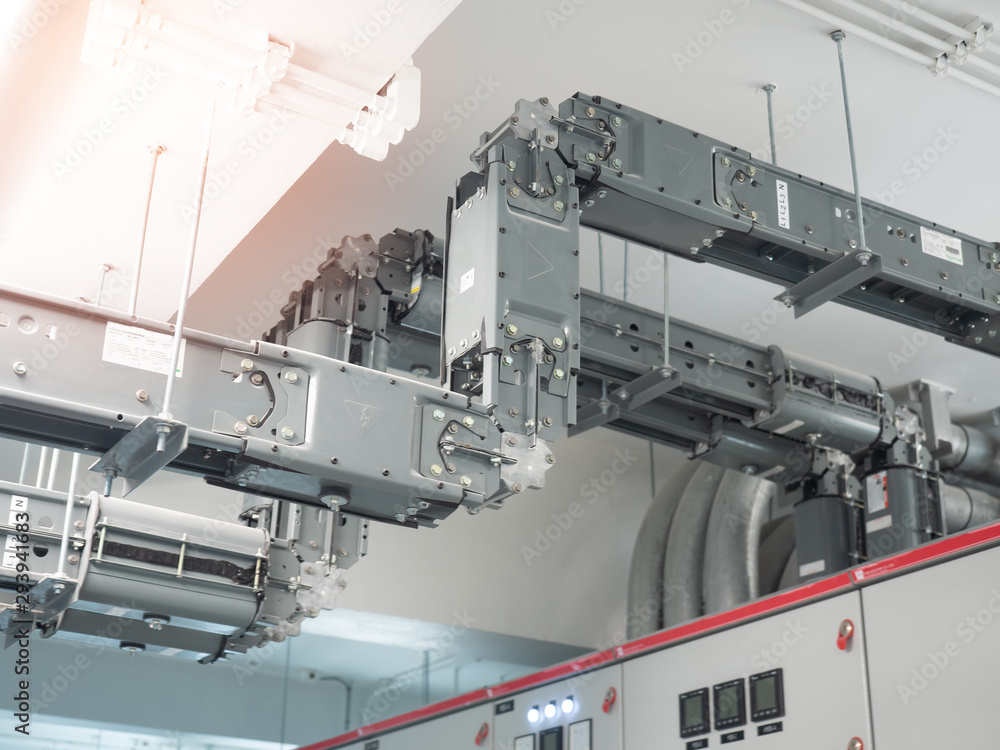

Credit: www.abposters.com

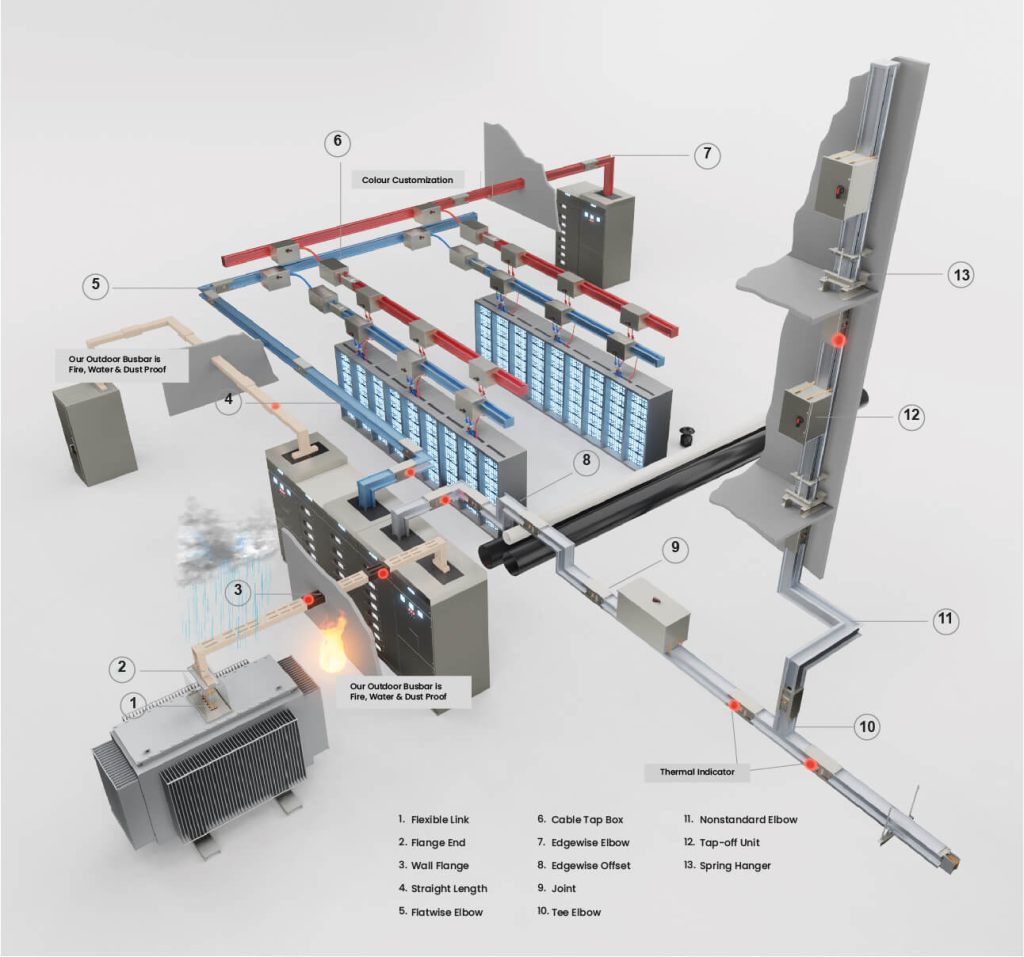

Main Components of Busbar Trunking

Busbar trunking systems have several parts. Each part has a job. Let’s look at these components.

1. Busbars

Busbars are metal strips. They carry electricity. These strips are inside the trunking. Busbars are made from copper or aluminum. Copper is better but more expensive. Aluminum is cheaper but less efficient.

2. Trunking

Trunking is a protective cover. It holds the busbars inside. Trunking can be made from metal or plastic. It keeps the busbars safe from damage. It also prevents people from touching the busbars.

3. Insulation

Insulation is a material that stops electricity from leaking. It covers the busbars inside the trunking. Insulation can be made from many materials. Some common ones are PVC and rubber.

4. Joints

Joints connect two sections of busbar trunking. They allow electricity to flow between sections. Joints must be strong and secure. They can be bolted or welded together.

5. Tap-off Units

Tap-off units are used to take electricity from the busbar trunking. They connect to the busbars inside the trunking. Tap-off units supply power to machines and lights.

6. Supports And Hangers

Supports and hangers hold the trunking in place. They attach to walls or ceilings. Supports and hangers keep the trunking steady. They stop it from moving or falling.

7. End Covers

End covers are caps. They close the ends of the busbar trunking. End covers stop dust and dirt from getting inside. They also keep people safe from touching live busbars.

8. Expansion Joints

Expansion joints allow the busbar trunking to expand and contract. This happens when the temperature changes. Expansion joints prevent damage to the trunking.

Why Are These Components Important?

Each component plays a key role. They work together to make the system safe. They also make it efficient. Let’s see why these components are important.

- Busbars: They carry electricity. Without busbars, the system cannot work.

- Trunking: It protects the busbars. It also prevents accidents.

- Insulation: It stops electricity from leaking. This makes the system safe.

- Joints: They connect sections. They allow electricity to flow smoothly.

- Tap-Off Units: They provide power to devices. This makes the system useful.

- Supports and Hangers: They hold the system in place. This prevents damage.

- End Covers: They keep the system clean. They also ensure safety.

- Expansion Joints: They allow the system to handle temperature changes. This prevents damage.

Credit: trentongcc.com

How to Maintain Busbar Trunking Systems

Maintenance is important. It keeps the system working well. Here are some tips.

- Check the busbars regularly. Look for any signs of damage.

- Inspect the insulation. Make sure it is not worn or cracked.

- Ensure joints are secure. Tighten any loose bolts.

- Clean the trunking. Remove any dust or dirt.

- Test tap-off units. Make sure they are providing power correctly.

- Check supports and hangers. Ensure they are holding the system firmly.

- Inspect end covers. Make sure they are in place.

- Check expansion joints. Ensure they are working well.

Frequently Asked Questions

What Are Busbar Trunking Components?

Busbar trunking components include conductors, insulation, enclosures, and joints. They help distribute electrical power efficiently.

How Does Busbar Trunking System Work?

Busbar trunking systems distribute electricity through enclosed conductors. They ensure safe and reliable power distribution.

Why Use Busbar Trunking Systems?

Busbar trunking systems save space, reduce installation time, and increase flexibility. They are ideal for modern electrical setups.

What Materials Are Used In Busbar Trunking?

Busbar trunking often uses copper or aluminum conductors. These materials ensure efficient power flow and durability.

Conclusion

Busbar trunking systems are key in electrical setups. They make electricity distribution safe and efficient. Understanding the components helps in maintaining the system. Regular checks and maintenance keep the system running well. This ensures safety and reliability.